Despite all of the hoohah around whale-shaped wheels and crazy wide “cravel” wheels and the return of the V shaped aero wheel and all of the rest of the “hey look at me now!” stuff on cycling news and review sites, it’s possible that more people are actually looking forward to owning a new AForce Al33-based set of wheels than any other. We’ve had a set for several months now, I rode them for the majority of the summer and have had a few friends get after it on them since, and the response has been universally glowing. My personal inclination is to say that they’re the best carbon clinchers I’ve ever ridden – more on that in a bit.

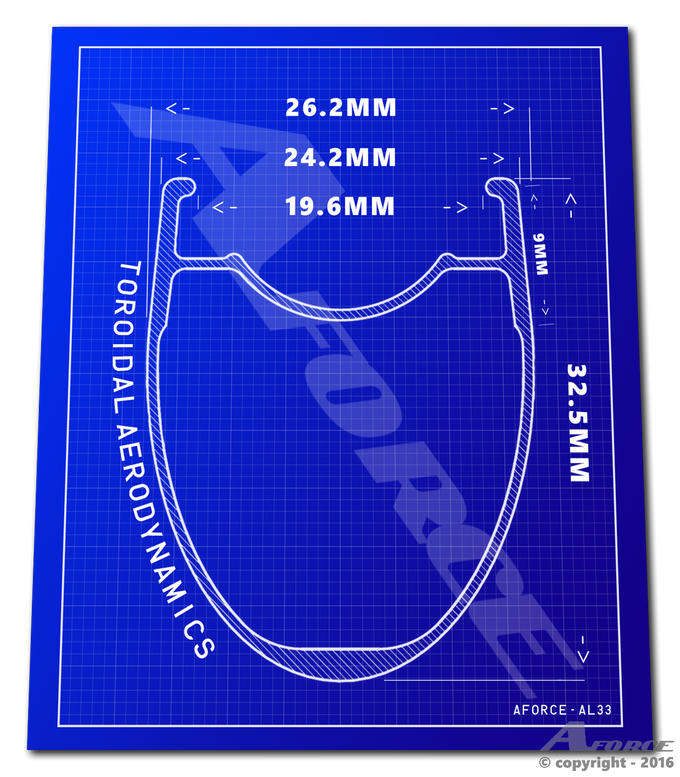

To review, the Al33 is 32.5mm deep, 26.2mm wide (max) 25mm wide (brake track), and 19.6 wide (internal). Our test set of rims weighed 470 and 474g. The brake track is coated with a unique ceramic-ish coating that both allows an alloy wheel to have a durable black brake track, and it provides a really hard finish so your brake pads and not your brake track gets most of the wear. It’s tubeless ready, although of course regular clinchers fit and work just great on them (I installed a Schwalbe One today without any levers, then inflated with a pump, though this performance can not be guaranteed for every tire every time). Valve stems on tubes should be 48mm, while Stan’s 44mm tubeless valves fit perfectly if you want to go that way.

The rims are made of a slightly different alloy than standard bike rims, which feels and sounds harder than standard rims. Measured stiffness is outstanding, and durability has been great so far (our test set has about 2000 miles on it thus far – a little more on the front, a little less on the rear).

Though the eye, arm, speedometer, and butt-mounted aerodynamics sensors all point to this being a quick and easy to handle set of wheels, we are arranging a wind tunnel test on behalf of the manufacturer and distributor in order to verify this. We hope to have that test complete by the end of the month.

For our builds, we will be doing both a standardized build with your choice of our black hubs or black White Industries T11 or CLDs and bladed spokes (which will inherit the RFSW moniker), and a full range of custom road and disc builds with any of the other hub and spoke components we use.

Darn sexy, huh?

Darn sexy, huh?

Our perhaps uncharacteristic silence on the project has been because we just didn’t want to jerk anyone’s chain too much before we knew that the rims were made, through QC, and on a boat headed to the distributor. That has now all happened, so we have constructed the site pages where you can check out all the options (go into the store and then into the "Custom" section for REALLY all the options) and pricing.

We are scheduled to get our first rims in late February, and will ship completed builds as soon thereafter as possible. Given the vagaries of shipping, customs delays, domestic shipping, and our rapturous joy at getting “are they here yet?!?!?!? I NEEEEEEEED them for a ride this weekend!!!!!!!!!!!!!” emails, it would be prudent to consider that earliest in hand delivery will be around March 10th.

33 comments

Only ceramic for now?

Hi Travis, There's zero carbon hate, rather an opposing view to the sentiment that carbon makes anything better. Rail 52, when it was launched, was totally unique – 18mm inner width which we still feel is the correct all around choice for a wheel of that depth with a road-focused mandate, in a very wind-stable design (blew the doors off of shallower wheels for stiffness when tested), and as fast as the benchmark deeper wheel when you look at the most rider-relevant yaw angles. Those attributes, which were only possible in carbon, made it unique. At the time, the Velocity A23 and HED Belgium C2 and an American Classic rim were the main wider alloy rims on the market, and the A23 turned out to leave quite a big gap to even the v-shaped 38mm carbons we did back then. Fast forward 18 months from there and the Kinlin XC279 goes just as fast as those old 38s in the wind tunnel, giving away 10mm of depth as well as providing an extra 3.5mm of interior width. And alloys have continued to progress from there.Putting another "me too" carbon wheel out there for the sake of having a carbon wheel makes no sense to us. The fastest wheels will always be carbon (until that gets displaced in the future). Those fastest wheels will also still come with the penalties of cost, weight, handling performance, and braking compromise. Rail 52s have excellent aerodynamics, and you might see .2mph gain using them versus good mid-depth alloys – assuming you aren't drafting when your savings will be cut by over 25%. And yet as recently as this week, carbon wheel vendors are telling people that it's typical to see a 1 to 2mph speed increase when going to deeper carbon wheels. Carbon has its place. As stated, the fastest wheels will always be carbon, but they are not without downsides. There's a strong case for it in mountain bike wheels as it's much lighter than equivalently strong/stiff/wide alloys, but it comes with a big cost increase. So no, there's zero carbon hate going on here. We hate that it gets billed as a 100% categorical, no downsides, always better in every venue rim solution by other wheel brands. A wheel with the aerodynamics of the 52, used where those aerodynamics can bear themselves out, is one such case where carbon has merit.

Hi Greg, To start, just ceramic. I'm not 100% sure what's being brought in but if people want normal machined brake tracks and it's available we'll set that as an option somehow.

How's the brake pad wear pattern with the non-parallel brake tracks?

Joe – Good question. The brake track can't has more or less no observed impact on pad wear, but carbon pads actually work best. AForce sells pads, but we have been using some carbon pads that we have and can still get and they've been great. Probably good for ~3000 miles if you ride in reasonably dry conditions, depending of course on your weight and how hilly it is where you are. We'll supply a set of those with each set. Regular alloy pads gets hammered pretty hard by the brake track's hardness. The brake track is really hard wearing in our experience.