Despite all of the hoohah around whale-shaped wheels and crazy wide “cravel” wheels and the return of the V shaped aero wheel and all of the rest of the “hey look at me now!” stuff on cycling news and review sites, it’s possible that more people are actually looking forward to owning a new AForce Al33-based set of wheels than any other. We’ve had a set for several months now, I rode them for the majority of the summer and have had a few friends get after it on them since, and the response has been universally glowing. My personal inclination is to say that they’re the best carbon clinchers I’ve ever ridden – more on that in a bit.

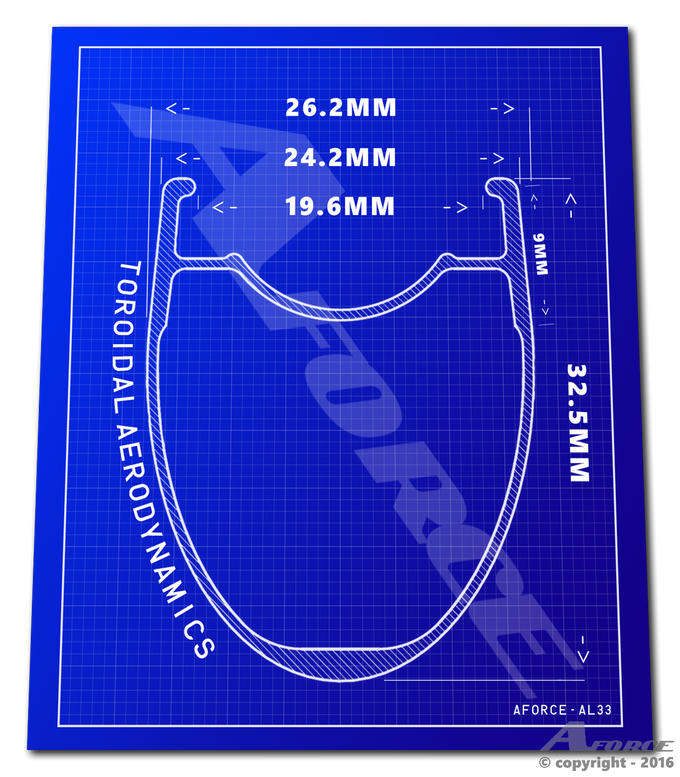

To review, the Al33 is 32.5mm deep, 26.2mm wide (max) 25mm wide (brake track), and 19.6 wide (internal). Our test set of rims weighed 470 and 474g. The brake track is coated with a unique ceramic-ish coating that both allows an alloy wheel to have a durable black brake track, and it provides a really hard finish so your brake pads and not your brake track gets most of the wear. It’s tubeless ready, although of course regular clinchers fit and work just great on them (I installed a Schwalbe One today without any levers, then inflated with a pump, though this performance can not be guaranteed for every tire every time). Valve stems on tubes should be 48mm, while Stan’s 44mm tubeless valves fit perfectly if you want to go that way.

The rims are made of a slightly different alloy than standard bike rims, which feels and sounds harder than standard rims. Measured stiffness is outstanding, and durability has been great so far (our test set has about 2000 miles on it thus far – a little more on the front, a little less on the rear).

Though the eye, arm, speedometer, and butt-mounted aerodynamics sensors all point to this being a quick and easy to handle set of wheels, we are arranging a wind tunnel test on behalf of the manufacturer and distributor in order to verify this. We hope to have that test complete by the end of the month.

For our builds, we will be doing both a standardized build with your choice of our black hubs or black White Industries T11 or CLDs and bladed spokes (which will inherit the RFSW moniker), and a full range of custom road and disc builds with any of the other hub and spoke components we use.

Darn sexy, huh?

Darn sexy, huh?

Our perhaps uncharacteristic silence on the project has been because we just didn’t want to jerk anyone’s chain too much before we knew that the rims were made, through QC, and on a boat headed to the distributor. That has now all happened, so we have constructed the site pages where you can check out all the options (go into the store and then into the "Custom" section for REALLY all the options) and pricing.

We are scheduled to get our first rims in late February, and will ship completed builds as soon thereafter as possible. Given the vagaries of shipping, customs delays, domestic shipping, and our rapturous joy at getting “are they here yet?!?!?!? I NEEEEEEEED them for a ride this weekend!!!!!!!!!!!!!” emails, it would be prudent to consider that earliest in hand delivery will be around March 10th.

33 comments

Do you have a german distributer or do you deliver to other dealers and wheelbuilders?

Hi Speedware -We aren't the manufacturer or even the US importer. If you send your email address I can put you in touch with AForce directly, or you can contact them thru their Facebook page.Dave

I have a Aforce A133 and here the things that I want to say about my sexy bike !The wheels themselves are alluring if downplayed things. The earthenware brake track is a dull, matt dim, while the complete on whatever is left of the edge is professional and not very polished. We ought to note that the generation wheels will have a few decals included, so we don't know precisely what the completed item will resemble. AForce is firmly master tubeless, yet there's nothing to stop you utilizing tubes. Truth be told, not at all like with some tubeless wheelsets, the Al33s don't make tire mounting excessively troublesome; I experienced no difficulty influencing an arrangement of 25mm Continental GP4000Ss onto the edges with two layers of tubeless tape set up.