There is lots to digest from that title alone. Let's start with the name of our new wide carbon clincher - the Rail. The phrase "corners like it was on rails" is as ubiquitous to high end bike reviews today as "laterally stiff, vertically compliant" was a few years ago. The difference is that it actually means something to racers. Cornering matters. If you do it with confidence and aplomb, it's free speed. If you're unsure or cautious, gaps open that you have to burn matches to close. We're calling our new wheel the Rail because it is designed not just to excel in the wind tunnel, but in the real world as well. Racing is accelerating, holding speed on the flats, climbing, bombing descents and railing corners. When we thought about what attributes we wanted to design into a new racing wheelset, we kept all of this in mind. The Rail is (we think) the first wheel optimized for every part of the race course.

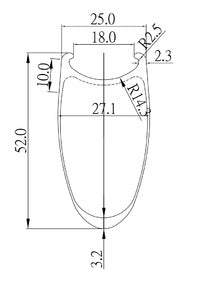

That leads us to the next part of the title of this blog I want to focus on - Wide. What is a wide rim? The most common answer is 23mm. But if you think about the attributes of a wide rim - that it results in less casing deformation and broadens the tire's contact patch on the road, increasing road feel and traction - it becomes clear that the width that matters is not the brake track width, but the inside width. The inside width of the Rail is 18mm. By comparison (and not coincidence) the inside width of the Velocity A23 rims we use in our alloy FSWs is also 18mm. We positively love the road feel of good rubber on a set of our FSWs, and deliberately modeled the Rail to replicate that feel with the same inside width.

That leads us to the next part of the title of this blog I want to focus on - Wide. What is a wide rim? The most common answer is 23mm. But if you think about the attributes of a wide rim - that it results in less casing deformation and broadens the tire's contact patch on the road, increasing road feel and traction - it becomes clear that the width that matters is not the brake track width, but the inside width. The inside width of the Rail is 18mm. By comparison (and not coincidence) the inside width of the Velocity A23 rims we use in our alloy FSWs is also 18mm. We positively love the road feel of good rubber on a set of our FSWs, and deliberately modeled the Rail to replicate that feel with the same inside width.

But alloy brake tracks are thinner than those on carbon clinchers. In order to achieve an 18mm inside width, we needed to expand the brake track to 25mm wide. So technically the Rail is 25mm wide at the brake track, but when we say "Wide" we're actually referring to the 18mm wide on the inside. That's the wide that matters.

By way of reference, here are the brake track and inside widths of some other popular clincher rims:

RIM: Brake Track / Inside

November Rail: 25.0mm / 18.0mm*

ENVE SES: 26.0mm front, 24.0mm rear / 18.0mm front, 15.5mm rear*

November FSW: 22.7mm / 17.8mm

HED C2: 23.0mm / 17.2mm

Stan's NoTubes Alpha: 20.2mm / 17.1mm

Zipp 404 Firecrest: 23.5mm / 16.25mm*#

Mavic Open Pro: 19.7mm / 14.5mm

November RFSC: 21mm / 14.0mm

Mavic Ksyrium: 20mm / 14.0mm

Kinlin XR-300: 18.5mm / 13.7mm

*carbon rim

# Brake track width measured at the tire bead. Zipp FC rims widen to 25.2mm at the bottom of the brake track.

You'll see that the delta between inside and brake track width is higher on carbons, which means that a rim that the brand describes as 23mm or even 25mm wide may actually have a narrower inside - where it matters - than a 20mm wide alloy. The width at the brake track likely does matter in the wind tunnel, which is easier to measure and market than "road feel" (something I expect we'll learn all too well in the near future), but our philosophy is that inside width matters more for wheels designed to race fast instead of test fast.

This solid plastic prototype of the Rail goes to the wind tunnel for preliminary testing next week.And the final word from the blog title I want to point at here is Proprietary. We've made no secret of our practice of using open mold rims and framesets. Our belief is that performance is a meaningful differentiator, but simply being different does not always mean improved performance. We really like our original open mold RFSCs for their light weight, stiffness and durability. When we elected to switch to a wide carbon clincher however, we couldn't find anything in an open mold that offered the performance we wanted. We found rims at 23mm - 24mm wide, but the inside width wasn't the 18mm or so that we feel strongly is critical for all-around race performance. We also see the trend of going as wide as possible in the bulge for aerodymamics, but that adds a lot of weight that racers jumping out of 80 corners every Saturday start to pick up on. When we couldn't find what met our needs in the market, we set out to build it ourselves. Starting from scratch was the only way we could offer what we think is the ideal racing wheelset, combining road feel, aerodymanics and low rim weight (our target for the Rail is between 475g and 495g).

This solid plastic prototype of the Rail goes to the wind tunnel for preliminary testing next week.And the final word from the blog title I want to point at here is Proprietary. We've made no secret of our practice of using open mold rims and framesets. Our belief is that performance is a meaningful differentiator, but simply being different does not always mean improved performance. We really like our original open mold RFSCs for their light weight, stiffness and durability. When we elected to switch to a wide carbon clincher however, we couldn't find anything in an open mold that offered the performance we wanted. We found rims at 23mm - 24mm wide, but the inside width wasn't the 18mm or so that we feel strongly is critical for all-around race performance. We also see the trend of going as wide as possible in the bulge for aerodymamics, but that adds a lot of weight that racers jumping out of 80 corners every Saturday start to pick up on. When we couldn't find what met our needs in the market, we set out to build it ourselves. Starting from scratch was the only way we could offer what we think is the ideal racing wheelset, combining road feel, aerodymanics and low rim weight (our target for the Rail is between 475g and 495g).

Does this mean we're abandoning open molds altogether? Not necessarily. What it means is that we will take whatever path necessary to pursue a product strategy that keeps November at the intersection of performance and value, even as the bar is raised on both.

Also, start training, seriously. It's January for chrissake.

11 comments

Mike, I'm really really excited about your wheelset. I've lurked a long time on your site, watching November grow and grow from the beginning, please keep up what you're doing.By way of asking, I'm a big power sprinter (210 on race days, with no shortage of torque) and tend to put a hurting on my equipment. Was considering a set of SES, but have decided to wait and see how development of the Rail goes to possibly save money and do business with November. Here are a few things that are really important to guys my size. Durable and Heat Resistant Brake track – Your inner/outer width measurements look really good, crushing a brake track because you hit a pothole or two sucks a lot.If there is anyway to get a durable heat resistant/dissipating resin in the brake track (a la zipp and others) that would be awesome. Option of Steel or Alu Freehub bodies. – my current 'stallion' wheels force me to run a sram red cassette to avoid shredding the lightweight alu freehub body to pieces (i mean notching them all the way around untill cogs start spinning) . They also machined the spines to half height to save weight as well as reduced material back where the pawls are, resulting in tons of cracks and snaps (as of this writing I'm on body # 5). If people have the option great, otherwise I will probably have to buy just the rim and find a good hub. I think you guys are going to do great with this and I will be watching very closely, cash in hand.C

I'm looking forward to the testing results and availability. What size(es) will be available and when?

Cedrick – Thanks. We're working on braking heat through a couple of ways. No brake track is impervious (not even the one that claims it is, I've seen one of those fail – granted it was in 'designed to fail' circumstances) but it's a very manageable situation. Hit the wrong pothole, you hit the wrong pothole, but we want to make the threshold for that as high as reasonable. A 700 gram manhole cover of a wheel would pretty much eliminate that, but no one would ever find out in the real world because no one would ride it. On cassette bodies, we have the option of the Anti Bite Guard on our standard black hubs, which comes standard on the red hubs. White Industries hubs have a titanium cassette body that will outlive all of us, and Kings have a titanium drive ring with an aluminum cassette body which is stunningly durable. We have no plans to sell the rims by themselves, but our hub options should make that a non-issue in any case. Ric B – 52 is the depth, and the when question will depend on several things. We plan on shipping mid to late spring if things stay on track.

Are the new wide tubulars proprietary too?

Thanks for the detailed answer Dave! Have you guys looked at Alchemy elf/orc hubs for this wheel? Seem like a great option to build into a really strong, stiff wheel… though the WI T11 is killer too.